What Classes Do You Have to Take for Welding

To become a welder, you will need to take a variety of classes and gain practical experience.

These include certificate programs in welding, apprenticeships under a qualified welder, and high school diploma or equivalent.

Further education can be obtained through community college or technical school courses.

On-the-job experience gained through apprenticeship is also crucial, as well as formal education and training programs that can range from a few months to two years.

Math and science subjects are taught at welding tech schools, along with vocational school and community college courses.

Additionally, specific job roles such as welding inspector or manufacturing welding technician may require specialized training.

It is important to gain experience in the field, become a certified welder, and possess strong math skills including fractions, decimals, formulas, and trigonometry.

Did You Know?

1. In addition to welding-specific courses, aspiring welders are typically required to take classes in applied mathematics. This is because welding involves precise measurements and calculations to ensure the strength and integrity of the welds.

2. Many welding programs also include courses in metallurgy, which is the study of metals and their properties. This knowledge is crucial for welders as different metals require varying techniques and procedures to achieve high-quality welds.

3. Welding students often have to take classes in blueprint reading and interpretation. This is because welders need to be able to understand technical drawings and schematics to accurately determine the specifications and welding requirements of a project.

4. Safety is a top priority in the welding industry, which is why welding students are often required to take classes in occupational safety and health. These courses teach students about proper safety protocols, hazard identification, and the use of protective equipment to minimize the risks associated with welding.

5. While not a required class, many welding programs offer courses in art and design. This is because welding can be a versatile skill that is not limited to industrial applications. Some artistic welders create sculptures, ornamental pieces, or even architectural structures, so having a foundation in art and design can be beneficial in exploring creative avenues within the welding field.

Certificate Programs In Welding

Obtaining a certificate in welding is one of the first steps towards a career in this field. These programs provide a solid foundation in essential welding techniques, safety protocols, and industry standards. Students can choose from a variety of courses, including Introduction to Welding, Shielded Metal Arc Welding (SMAW), Gas Metal Arc Welding (GMAW), and Flux-Cored Arc Welding (FCAW).

Certificate programs typically cover the basics of welding, such as metal preparation, joint design, and welding terminology. Students also gain hands-on experience through practical training sessions. These programs may require students to complete a certain number of hours in a welding lab, where they will practice various welding techniques under the supervision of experienced instructors.

Furthermore, certificate programs often include courses on welding safety and the proper use of welding tools and equipment. Students will learn about personal protective equipment (PPE), fire safety, and hazard prevention. Additionally, they will become familiar with welding codes and standards, ensuring their work meets industry regulations.

Apprenticeships And On-The-Job Experience

In addition to certificate programs, aspiring welders must gain on-the-job experience through apprenticeships. Apprenticeships offer valuable hands-on training alongside experienced welders, providing opportunities to enhance skills and develop a deep understanding of the trade.

During apprenticeships, individuals work under the close supervision of qualified welders, allowing them to learn from real-world projects. This on-the-job experience provides a practical application of the knowledge gained in certificate programs. Apprentices gain exposure to different welding techniques, materials, and environments, which helps build their versatility and problem-solving abilities.

Apprenticeships may last anywhere from 1 to 4 years, depending on the program. During this time, apprentices earn a salary while learning and refining their skills. They acquire an in-depth knowledge of welding processes, machinery, and welding codes. This practical experience is crucial for mastering the art of welding and transitioning to professional work.

- Apprenticeships offer hands-on training alongside experienced welders.

- Apprentices gain exposure to different welding techniques, materials, and environments.

- Apprenticeships can last from 1 to 4 years, depending on the program.

- Apprentices earn a salary while learning and refining their skills.

- Practical experience gained through apprenticeships is crucial for mastering the art of welding.

High School Diploma Or Equivalent

Before pursuing a career in welding, individuals must possess a high school diploma or its equivalent. This educational prerequisite helps ensure that students have a solid foundation in basic academic subjects, including math, science, and communication skills.

A high school diploma demonstrates that a candidate has acquired essential skills and knowledge that can be applied to the welding profession. It also serves as an indication of commitment and dedication to completing educational requirements.

While a high school diploma is the minimum requirement, it is advisable for aspiring welders to take courses relevant to the field. High school courses in physics, chemistry, mathematics, and technical subjects can provide a strong academic foundation for future welding studies.

Community College And Technical School Courses

Community colleges and technical schools are great options for students looking to enhance their welding skills and knowledge. These institutions offer a wide range of welding courses, including advanced techniques and specialized areas.

The courses at community colleges and technical schools are specifically designed to prepare students for industry demands. They aim to bridge the gap between theoretical knowledge and practical application. Some of the courses offered include Advanced Welding Techniques, Introduction to Materials Engineering, and Welding Fabrication and Inspection.

One of the benefits of attending these institutions is the opportunity to specialize in specific areas of welding. Students can choose to focus on pipe welding, sheet metal welding, or structural welding, among others. These specialized courses provide focused training and allow students to develop expertise in their chosen area of interest.

Math And Science Subjects At Welding Tech Schools

Mathematics and science play a crucial role in welding education, providing a solid foundation for understanding welding processes, calculating measurements, and interpreting technical drawings.

At welding tech schools, students will typically engage in mathematics courses, covering topics such as fractions, decimals, geometry, formulas, and trigonometry. These math skills are essential for calculating angles, measuring and cutting materials, and determining welding parameters.

In addition to mathematics, science subjects such as physics and chemistry are also vital for welders. They help in comprehending the properties of different metals and their reactions during the welding process. Students will learn about melting points, thermal expansion, and the behavior of metals under various conditions. This knowledge enables welders to make informed decisions and produce high-quality welds.

To summarize, the path to becoming a professional welder involves a combination of certificate programs, apprenticeships, high school education, and community college or technical school courses. Focusing on math and science subjects is crucial. Each component contributes to building a strong foundation in welding techniques, safety practices, and industry standards.

- Mathematics courses cover topics such as fractions, decimals, geometry, formulas, and trigonometry.

- Science subjects like physics and chemistry are essential in understanding the properties of different metals and their reactions during welding.

- Practical experience and completion of required classes are crucial in progressing towards a successful career in welding.

Check this out:

Frequently Asked Questions

Which subjects are required for welding?

In order to pursue a career in welding, several subjects are necessary to master. One of these fundamental subjects is mathematics, as it plays a crucial role in measuring and calculating various welding parameters. Additionally, engineering science provides welders with the necessary knowledge in metallurgy and materials, enabling them to understand the behavior of metals during the welding process. Another essential subject is structural steel drawing, which provides welders with the ability to interpret technical drawings and understand the specific requirements of a welding project. Lastly, welders theory is indispensable, offering theoretical insights into different welding techniques and principles, further enhancing their expertise in the field of welding.

What is basic welding course?

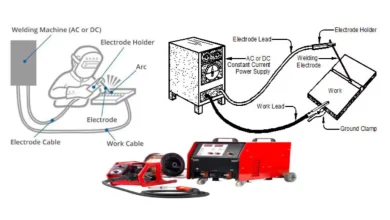

The basic welding course is designed to provide individuals with the necessary skills and knowledge to perform ARC welding. Through this course, participants will learn how to effectively use electricity to generate heat that can melt metal and subsequently bind it together. By the end of the course, students will have a solid foundation in ARC welding, enabling them to tackle simple welding projects and contribute to various metalwork tasks. With a focus on safety precautions and practical hands-on experience, this course equips participants with valuable skills in the field of welding.

Does welding require math?

Yes, math is crucial in welding. A proficient welder needs to possess knowledge of fractions, decimals, geometry, formulas, and trigonometry. These mathematical skills enable them to create robust welds, regardless of the material they are working with. While understanding the melting point of a metal is just one example of a valuable mathematical skill, the role of math extends far beyond that, encompassing various calculations and measurements necessary to achieve precise and flawless welding.

How long does it take to learn welding?

The duration of time it takes to learn welding depends on the specific program and individual dedication. Welding certificate programs typically range from a few weeks to six months. These programs provide comprehensive coverage of welding theory and basics, equipping students with the necessary skills to enter the workforce. The length of time required to grasp welding techniques and obtain proficiency is influenced by the commitment and focus of the learner.