How to Make Saw Horses

To make saw horses, you can follow a set of plans available from various sources such as Fine Homebuilding or Jay’s Custom Creations.

These plans typically involve constructing a sturdy and durable sawhorse using different materials and techniques.

You can choose to build them with compound miters, which may require slightly more effort but result in a stronger design.

It is recommended to label and assemble each component one at a time to simplify the process, and with patience and attention to detail, the construction can be completed in a couple of hours.

The resulting pair of sawhorses can be used for a wide range of tasks, including sawing, painting, and serving as a platform for scaffolding.

Additionally, there are commercially available options, such as steel brackets or ready-made sawhorses from stores like The Home Depot, which offer features like folding legs, handles for portability, adjustable legs for uneven terrain, and high weight capacity.

Balded on their quality and maintenance, the sawhorses you make or acquire can last a lifetime or even be passed down to future generations.

Check this out:

Did You Know?

1. Did you know that the world’s largest saw horses were built in Japan and stood at an impressive height of 15 feet? These colossal structures were constructed to assist in building large-scale wooden structures in a fraction of the time.

2. The concept of using saw horses dates back to ancient Egypt, where they were depicted in wall paintings that date back over 4,000 years. It just goes to show that this simple tool has been invaluable throughout history.

3. The term “saw horses” is said to have originated from the medieval period, as these tools were traditionally made from horse or donkey legs, providing stability and strength.

4. The iconic “V” shape of the saw horse design is not just for aesthetics; it also enhances stability when cutting wood. This simple yet effective structure has remained virtually unchanged for centuries.

5. Despite their name, saw horses aren’t exclusively used for woodworking. These versatile tools have found their place in numerous industries, including building construction, film production, and even as supports for temporary stages during outdoor events.

History And Design Of Saw Horses

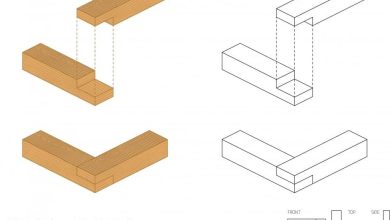

Saw horses have been a staple in workshops for over a century, with their design remaining relatively unchanged. These sturdy supports are low in height, allowing the use of knees to hold down work securely. The design also incorporates compound miters, which adds a level of complexity compared to other simpler designs. However, once you break down the construction into manageable steps, you can complete the process in just a couple of hours.

- Saw horses are a staple in workshops.

- Their design has remained relatively unchanged for over a century.

- They are sturdy supports that are low in height.

- Knees can be used to hold down work securely.

- The design incorporates compound miters, adding complexity.

- Construction can be completed in a couple of hours.

Construction Steps For DIY Saw Horses

To construct your own saw horses, it’s important to break down the process into individual components and label each one. This way, you can ensure accuracy and precision throughout the construction.

Here is the step-by-step process:

- Start by creating four legs, which should be cut to the desired height.

- Next, build a sturdy frame that connects the legs, providing stability and support.

- Additionally, create a top rail to add extra strength to the saw horse.

- Finally, once all the components are complete, simply assemble them together, securing the joints with screws, bolts, or nails.

Remember to measure accurately, follow the appropriate safety procedures, and use the right tools and materials for the job.

Note: Saw horses are essential tools for various construction and woodworking projects, providing a reliable and stable surface for cutting and supporting materials.

Long-Lasting And Versatile Uses Of Saw Horses

Saw horses are incredibly versatile workshop tools that provide a stable platform for cutting wood or other materials. They have multiple uses that make them an essential tool in any workshop:

- Sawing: Saw horses are commonly used for sawing, as their design provides stability and support for cutting tasks.

- Painting: The low design of saw horses makes them ideal for painting. They can easily support large panels without the risk of tipping, allowing for smooth and efficient painting.

- Scaffolding: Saw horses can also be used as makeshift scaffolding. This allows you to safely reach higher areas, making tasks like installing fixtures or reaching elevated surfaces much easier.

When constructed properly, saw horses can last a lifetime or even longer. This makes them an invaluable tool that can be passed down to future generations.

Cost-Effective Plans For Building Saw Horses

If you’re in need of cost-effective DIY plans for building saw horses, there are a few options available. Fine Homebuilding provides plans for a lightweight and sturdy sawhorse that can be constructed for approximately $50. These plans include detailed instructions, making them suitable for beginners. Another option is Jay’s Custom Creations, which offers plans for stackable saw horses. These plans are not only cost-effective but also space-saving, as the saw horses can be stacked when not in use.

Space-Saving Stackable Sawhorse Plans

When it comes to maximizing space in your workshop, stackable sawhorse plans are a great option. Jay’s Custom Creations offers plans specifically tailored for stackable saw horses. This design allows you to stack multiple saw horses on top of each other, taking up less floor space when not in use.

These plans provide step-by-step instructions on how to construct the saw horses, ensuring stability and durability while also saving valuable workspace.

Various Options For Purchasing Saw Horses

If building your own saw horses is not preferred, there are various options available for purchasing pre-made saw horses. Steel brackets can be purchased, allowing you to build your own saw horse using the brackets as a frame.

The Home Depot offers a range of options, including a plastic saw horse with a reinforced center shelf, perfect for light tasks such as painting. They also sell a pair of metal saw horses with folding legs and handles, providing portability for those who need to transport them to different job sites.

For heavy-duty applications, The Home Depot sells a robust saw horse with adjustable legs, ideal for uneven terrain, and support pegs for cutting sheet goods. This heavy-duty version can hold up to an impressive 1300 lbs, ensuring stability even with the heaviest workpieces.

Frequently Asked Questions

Are saw horses worth it?

Sawhorses prove to be an invaluable addition to any DIY enthusiast’s toolkit. Their versatile design and capabilities make them a must-have in a workshop. Whether you opt for a lightweight or heavy-duty model, these sturdy frames effortlessly assist in a wide range of tasks, from sawing to painting to scaffolding. Investing in sawhorses ensures that you have a reliable tool at hand to tackle various projects effectively and efficiently.

1. What materials and tools are needed to make homemade saw horses?

To make homemade saw horses, you will need a few materials and tools. Firstly, you will require two sturdy wooden boards of equal length to serve as the legs of the saw horses. These boards should be thick and durable to provide stability. Additionally, you will need two shorter boards of the same thickness to act as the crossbars that connect the legs.

In terms of tools, you will need a saw to cut the wooden boards to the desired lengths. You may also require a drill to create holes for attaching the crossbars to the legs securely. Finally, you will need screws or nails to fasten all the pieces together. With these materials and tools, you can easily fabricate homemade saw horses to assist you in various construction or woodworking projects.

2. Can saw horses be customized for specific projects or tasks?

Yes, saw horses can be customized for specific projects or tasks. Depending on the specific requirements of the project, saw horses can be adjusted or modified to accommodate different sizes or types of materials. For example, the height of the saw horses can be altered to meet the comfort level of the user, allowing for easier and more precise cutting. Additionally, attachments such as clamps or vices can be added to the saw horses to securely hold the materials in place during cutting or assembly. These customizations enhance the versatility and functionality of saw horses, making them suitable for a wide range of projects and tasks.

3. Are there any safety precautions to consider when using homemade saw horses?

Yes, there are several safety precautions to consider when using homemade saw horses. First, it is important to ensure that the saw horses are sturdy and stable. They should be made from high-quality materials that can support the weight of the objects being worked on, and the joints should be properly constructed to prevent any wobbling or collapsing.

Second, it is essential to use the saw horses on a level surface to prevent them from tipping over. Uneven or inclined surfaces can compromise the stability of the saw horses and increase the risk of accidents.

Additionally, it is important to use caution when placing heavy objects on the saw horses and to distribute the weight evenly. Overloading the saw horses can put strain on the structure and potentially cause them to collapse.

Lastly, it is recommended to wear appropriate safety gear, such as gloves and safety glasses, when using saw horses to protect oneself from any potential hazards or accidents.