Can You Take Welding in College

Yes, you can take welding in college.

Many technical schools offer welding training programs that can be completed in about one year.

These programs typically result in a welding certificate, and they cover a range of skills and topics such as welding in multiple positions, welding different types of steel, aluminum, and stainless steel, various arc welding processes, cutting and grinding, safety procedures, basic metallurgy, and blueprint reading.

After completing a training program, you can also take the AWS Certified Welder test, which provides a recognized credential and career advancement opportunities.

Overall, welding in college offers a quick start to a lucrative career with high demand and excellent entry-level salaries.

Did You Know?

1. In some colleges, welding programs offer unique opportunities for students to compete in national welding competitions, where they can showcase their skills and potentially secure employment offers before even graduating.

2. Did you know that welding has been used in the production of several iconic landmarks, including the Sydney Opera House in Australia? The intricate design of the Opera House’s shell required skilled welders to assemble its steel components.

3. One fascinating fact about welding is that it played a crucial role during World War II. Welding was essential for repairing and maintaining military equipment, ships, and vehicles, enabling quick and effective repairs on the front lines of battle.

4. Welding is not limited to metals; it can also be used to bond materials such as plastics and ceramics. This has significant applications in industries like automobile manufacturing, where plastic welding is used to join various components, ensuring structural integrity and durability.

5. Welding is an ancient practice that dates back to the Bronze Age, around 3000 BC. Some of the earliest evidence of welded metal comes from artifacts found in Eastern Europe, indicating that early civilizations already possessed the skills to join metal pieces through welding techniques.

High Demand For Welding Jobs In The Industry

The demand for welding jobs in the industry is currently at its peak. With the rapid expansion in construction, manufacturing, and infrastructure projects, there is a continuous and unwavering need for skilled welders. The versatility of welding makes it an essential skill in various industries, including automotive, aerospace, oil and gas, and shipbuilding.

Welding is the process of joining metal pieces together by melting and fusing them. It requires a high level of precision and expertise to create strong and durable welds. As the need for specialized welding techniques increases, the demand for qualified welders also rises. According to the Bureau of Labor Statistics, this demand is expected to continue growing in the coming years, with a projected 3% increase in welding jobs by 2029.

Excellent Entry-Level Salaries And Opportunities For Advancement

One of the attractive aspects of pursuing a career in welding is the excellent entry-level salaries it offers. Welders typically start with a competitive wage, often higher than the minimum wage, due to the high demand for skilled workers in the field. The median annual wage for welders, according to the Bureau of Labor Statistics, is around $43,410.

Moreover, welding offers ample opportunities for career advancement. As welders gain experience and additional certifications, they can move up the ladder and take on more specialized roles. The welding field provides opportunities for weld inspectors, welding supervisors, welding engineers, and welding instructors. These higher-level positions come with increased responsibilities and higher salaries, making welding a rewarding career choice.

Technical Schools Offer Welding Training Programs

For those interested in pursuing a career in welding, technical schools provide comprehensive training programs. These programs are designed to equip students with the necessary skills and knowledge for success in the industry. Technical schools focus on hands-on training, allowing students to practice welding techniques in a controlled environment under the guidance of experienced instructors.

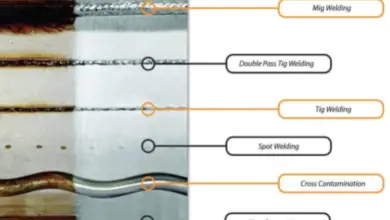

Welding training programs cover a wide range of topics, including:

- Welding in different positions on plate and pipe

- Working with various materials such as steel, aluminum, and stainless steel

- Mastering different arc welding processes

Additionally, students learn essential skills like cutting, grinding, and preparing materials for welding, as well as basic visual inspection of welds. They also gain knowledge in safety practices and procedures, basic metallurgy, reading blueprints and symbols, and other job-specific tasks.

“Technical schools provide comprehensive training programs for those interested in pursuing a career in welding. These programs focus on hands-on training and cover a wide range of topics, including welding techniques, working with different materials, and mastering arc welding processes.”

Programs Can Be Completed In About One Year

One significant advantage of pursuing welding in college is the relatively short timeframe for completing the required training programs. Unlike traditional four-year degree programs, welding programs can be completed in about one year, allowing individuals to enter the workforce quickly.

This shorter duration does not compromise the quality of education and training received. Technical schools focus on providing intensive and practical training, ensuring that students acquire the necessary skills within a shorter span of time. This quick turnaround time means that individuals can start earning a living sooner rather than later.

Welding Certificate Programs Typically Take 6-18 Months To Complete

Welding certificate programs are a popular option for those looking to kickstart their career in the field. These programs typically take between 6 to 18 months to complete, depending on the school and the curriculum. Certificate programs offer a focused and streamlined education that concentrates solely on welding skills, allowing students to fast-track their career prospects.

The average cost of completing a welding certificate program is around $33,000. While this may seem like a significant investment, it is important to note that it is much cheaper than a year of tuition at many private universities. Additionally, the long-term earning potential of a welding career makes it a worthwhile investment for many individuals.

The demand for welding jobs in the industry is soaring, with excellent entry-level salaries and opportunities for advancement. Technical schools offer welding training programs that can be completed in about one year, while welding certificate programs typically take 6 to 18 months to finish. With the quick start to a lucrative career that welding offers, it is clear why pursuing welding in college is a viable and rewarding option for many individuals.

Check this out:

Frequently Asked Questions

How long does welding course take?

To become proficient in welding, it is advisable to enroll in at least three courses. Nevertheless, for those aiming to excel in the competitive job market, it is advantageous to undergo further training. The entire program, including all the requisite classes, typically spans over a period of approximately 6 to 8 months.

Do welders have degrees?

Typically, welders do not require a formal degree from a college or university. In fact, a high school diploma is the most common educational attainment for welders, with 46% of graduates in this field holding this qualification. While some welders may choose to pursue an associate degree, only 18% of welder graduates opt for this path. The emphasis in welding is often on hands-on training and practical experience rather than formal academic degrees.

What type of welding pays the most?

The type of welding that pays the most is underwater welding. Underwater welders are in high demand due to the specialized skills required to work in the challenging underwater environment. They face unique hazards and therefore command higher salaries compared to other types of welders. This highly technical and dangerous job requires extensive training and certification, making it a lucrative career choice for those willing to take on the risks and challenges of underwater welding.

Another high-paying welding job is rig welding. Rig welders work in the oil and gas industry, where they are responsible for welding and repairing pipelines and oil rigs. The demanding nature of the job, coupled with the industry’s high stakes, results in rig welders earning top wages. Their expertise in welding heavy-duty structures and their ability to work in remote and potentially hazardous locations make them highly sought after and well-compensated in the field of industrial construction.

Is welding a hard?

Yes, welding can be quite challenging. It is a highly skilled trade that demands not only physical strength but also a great deal of technical knowledge. Welders must possess a keen eye for detail and be able to work with precision, as even the smallest mistake can have significant consequences. Additionally, the use of heavy machinery and exposure to high temperatures adds an extra layer of difficulty to the job. Therefore, it is essential to come fully prepared and committed to learning and mastering the craft before diving into the world of welding.